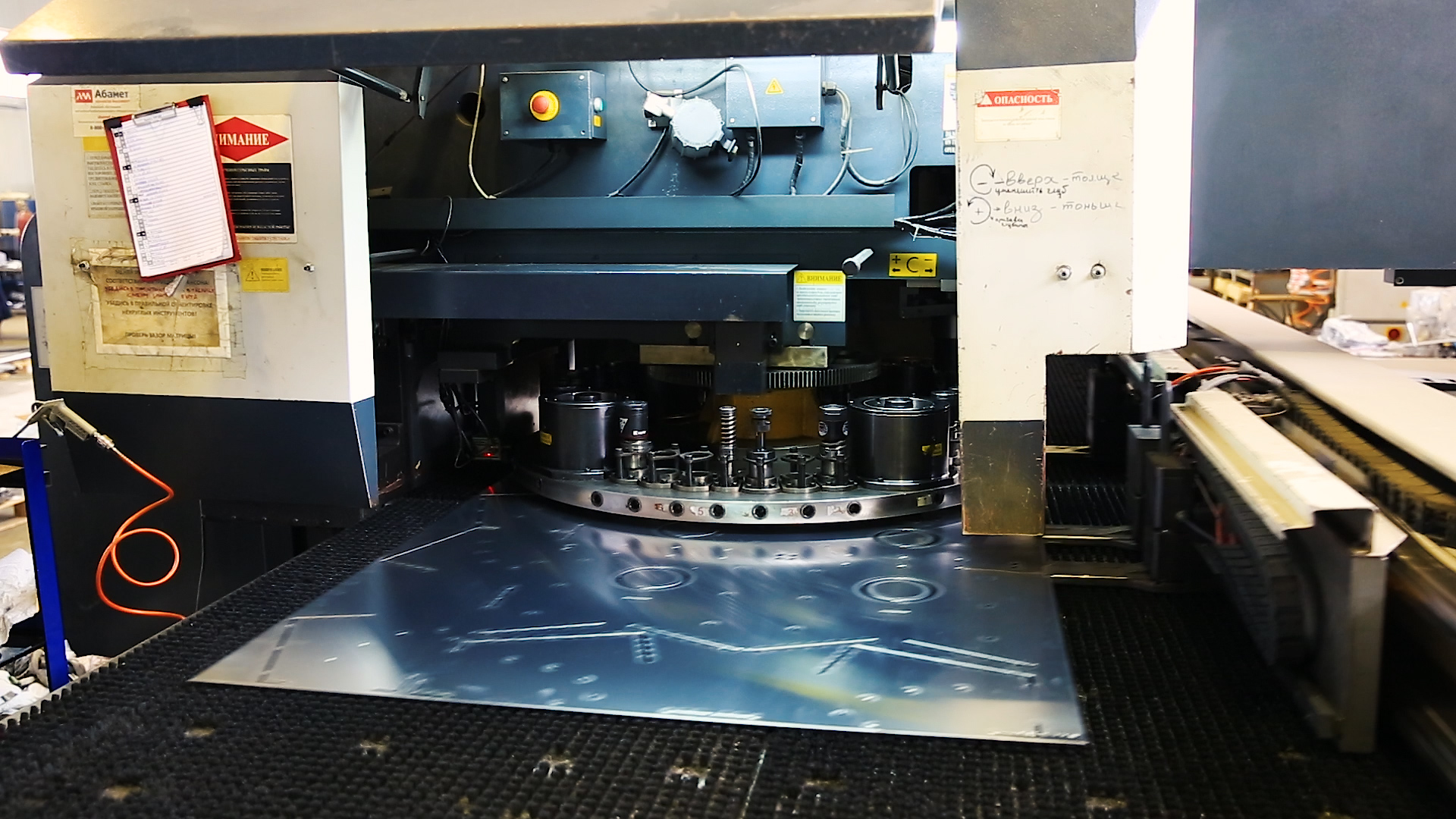

Perfolux has earned a worldwide reputation for precision metal fabrication and precision sheet metal punching, manufacturing key components that meet the most exacting tolerances. Our metal fabrication facilities are equipped with automated machinery from global leaders, including Finn-Power and others.

Controls allow individual automation solutions for diverse sheet metal punching applications – including the ability to punch, cluster punch, form, edge roll, rolling offset flanges, countersink, counterbore, emboss, louver, extrude, tap, hinge barrel punch form, deburr, part mark, etch, and cut blank extraction in the same process, for efficient, precise processing.

High Precision /Tight Tolerances – With position accuracy at +/- 0.004” (0.1016 mm) and repeatability to position at +/- 0.001” (.025 mm), Perfolux’s precision sheet metal punching services deliver the precision you require for your metal products. We have the capability to punch parts with complex patterns and complex geometries, while maintaining precision and high volume production rates.

Scratch-Free Processing – Our automated punching and panel bending / forming equipment provide precise movement of materials as they flow through the manufacturing process. Precision tooling eliminates burring and rough edges. As a result, your parts are manufactured scratch-free and imprint-free, reducing the need for polishing and finishing

Dedication – Our engineers and manufacturing staff are committed to providing each project with “best-in-class” design assistance, manufacturing process recommendations, and high quality, precision metal products – all supported by world-class customer service.

Flexible Processing

Many parts require multiple processes to complete. Parts with complex configurations and geometries can be produced to the tightest tolerances at production speeds, saving material and manufacturing costs.

Maximum Productivity

Perfolux is committed to maximizing the productivity throughout all operations in order to meet your production deadlines while minimizing production costs. Our commitment to manufacturing quality products will never be compromised.

We are committed to using the latest technology and automation in order to leverage innovations in production flexibility, accuracy and speed. Perfolux invests in equipment from industry-leading manufacturers, and ensures our staff is trained in the latest processes for sheet metal punching.

Our design and engineering staff reviews each design to determine the best method for sheet metal punching, and to determine if design modifications will improve performance or manufacturing efficiency and cost-effectiveness.