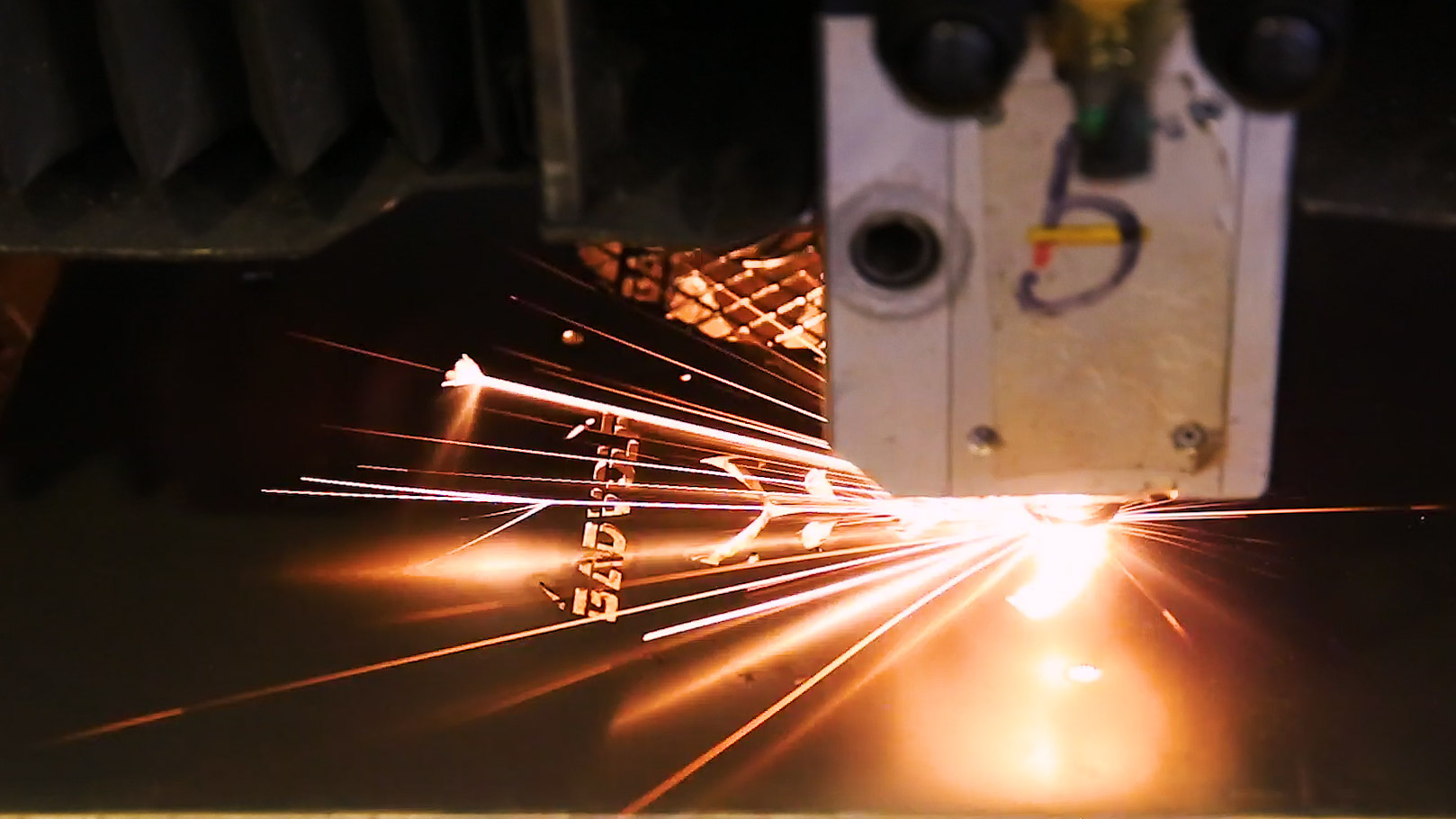

Laser cutting of metals has established itself in recent years as a cost effective, yet time-efficient technology with many applications. With extreme precision and high repeat-ability, cutting with a laser has clear advantages over other technologies.

Perfolux utilizes the latest laser cutting technology to provide you with a wide range of applications with a high degree of accuracy and flexibility. Laser processing improves productivity and offers competitive solutions to difficult processing applications.

We work in precise detail, to close tolerances. We maximize your material through effective nesting, leaving minimal waste. All of our processing is computer controlled, and we can work from your drawing, templates, mylars, scribed parts, or compatible CAD/CAM files. With a cutting-table size of 1.5 meters x 3 meters, we can cut large parts.

If you need quick turnaround, cost effectiveness, or improved processing, think of Perfolux as the solution for all of your laser cutting needs.

Laser Cutting Specifications and Capabilities

- Precision laser cut parts from sheet and plate ranging up to 60” (150 cm x 120” (300 cm) without repositioning; cutting up to:

- 20mm (.8″) thick carbon steel

- 10mm (0.4″) thick stainless steel

- 6mm (0.28″) thick aluminum

- Laser beam stability and cut speeds up to 2,300 inches per minute; travel speeds exceeding 4,700 inches per minute.

- Repeatable process control; tolerances held within +/- 0.004” (0.1016 mm)

- Complex shapes without tooling lead-time and costs; prototypes completed quickly and cost effectively.

- Laser cutting automation drives increases in efficiencies and cost reductions in manufacturing.

- Provides superior burr-free edge quality; Cut edge smoothness 125 microns.